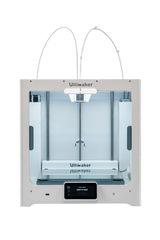

The New Ultimaker S5 Pro Bundle & Ultimaker S3 3D printer

Meet the New Ultimaker S5 Pro Bundle and Ultimaker S3 3D Printer

We are very excited to finally share these two exciting new products from Ultimaker. There is a lot to cover in this post so let's start with some highlight videos below:

Ultimaker S5 Pro Bundle |

Ultimaker S3 3D Printer |

|

|

But the magic of the Ultimaker S5 Pro Bundle is what happens when you put all of these products together

|

|

Industrial manufacturing capacity on your desktop

Ultimaker has created a one-of-a-kind manufacturing solution to offer engineers and designers the freedom and flexibility to do their best work. The Ultimaker S5 Pro Bundle enhances the award-winning Ultimaker S5 3D printer with the addition of the Material Station and Air Manager. Now you have the freedom to transform your workflow thanks to automated material handling, optimized air filtration, and controlled filament humidity. Combined, these revolutionary products allow you to boost productivity, add flexibility, and gain confidence to meet even your most demanding applications.

Now you can do more with less hassle

Thanks to humidity control, a massive 6 spool capacity, and boasting a market-leading range of materials, the Material Station takes care of all of your 3D printing material handling needs. Add to this the Air Manager's precise filtering control thanks to optimized software and pre-configured material profiles and you can experience industrial 3D printing like never before. The Air Manager takes care of your worries related to UFPs and allows for printing in every Ultimaker material as well as over 40 third-party filaments. This includes materials like glass and carbon fiber materials thanks to abrasive-resistant prefeeders in every bay of the Material Station.

Front loading and automated with NFC detection

With its's front loading 6-spool capacity and dependable automatic switching system, you can truly experience hassle-free printing with the Ultimaker S5 Pro Bundle. This system was designed from the ground up to run 24/7 completely unattended and deliver an in-house production experience to match your most ambitious projects. This is why the system allows you to load and eject materials, even while printing and still benefit for NFC reading capability.

A complete material and air quality solution

Now included in the Ultimaker Cura software are tested Air Manager fan control settings for every material. The Air Manager offers a EPA filter that removes 95% of ultrafine particles (UFPS) from the Ultimaker S5 build chamber. This large, replaceable filter catches, traps, or diffuses emitted particles. Cura Connect also allows for seamless integration with the Material Station for ideal print job distribution. This all combines to offer improved print results, efficient queuing, and optimal air filtration with zero hassle.

Seamless software integration

There is one more very powerful component of the Ultimaker S5 Pro Bundle that you can't see, free and intuitive Ultimaker software. Ultimaker Connect can queue print jobs digitally while Ultimaker Cura manages all of the settings related to fan speeds for each material. This combination along with the Ultimaker Marketplace allows for reliable printing of both Ultimaker and third-party filaments.

The bundle is conveniently available in two different configurations for both new and existing Ultimaker S5 customers. We are now accepting pre-orders and we expect to begin shipping by mid-October.

|

(Ultimaker S5 3D Printer included)

|

The Ultimaker S5 Pro Bundle Upgrade (Ultimaker S5 3D printer not included)

|

And now on to the second big announcement, the new Ultimaker S3 Studio 3D Printer!

-

A reinforced feeder - One of the immediate benefits of the Ultimaker S3 is it's reinforced, abrasion-resistant feeder. This enables printing with high-strength materials such as glass or carbon fiber composites when paired with CC Red Print Core.

-

Dual filament flow sensors - The new Ultimaker S3 offers flow sensors on both extruders which will pause your print to let you add a new spool when you run out.

- Integrated power supply - Rather than using an external power brick, the new Ultimaker S3 has an internal power supply making setup a breeze.

-

Advanced active leveling - The improved and precise active leveling functionality probes more points on the build plate to build a detailed height map of your printing surface. This ensures the perfect first layer for optimal bed adhesion.

-

High-accuracy stepper drivers - The same steppers which are used on the Ultimaker S5 have also been used on the new S3. These are quieter than previous generations to offer improved reliability and control.

-

A more rigid frame - This improved frame design helps to reduce vibrations which can cause ringing on your prints.

-

Single glass door - The integrated single glass door with magnetic latch offers more control of the build environment and also reduces warping and layer delamination on your prints.

-

Optimized internal design - Now you can utilize the entire build area while printing with dual extrusion offering an impressive build-volume-to-size ratio.

|

|

|