3D Printing in Medicine

How is 3D printing used in Medicine?

One of the foremost qualities of 3D printing is that you can create customized pieces for a select group of people. You are saving cost and time because you are not relying on high investments for molds and third party vendors. The medical field is a key opportunity for 3D printing as we can make people happy and healthy with minimal effort. So, we from Print Your Mind have investigated the potential of 3D printing for the emergence of new companies revolving around healthcare.

Enhancing Patient Care with 3D Printing at Jefferson Health

Thomas Jefferson University and Jefferson Health are truly at the forefront of healthcare technology. Doctors here are utilizing the many benefits 3D printing can offer them at Jefferson Health. 3D printers can help to better prepare students for challenges they will be faced with in the real-world and were integrated into their new Health Design lab.

3D Printing in a Trauma Hospital

The ETZ (Elisabeth-TweeSteden Ziekenhuis) is one of the eleven trauma centers in the Netherlands. As the only center in the country with trauma surgeons on location 24 hours a day, it serves as the main location for emergency patients in North Brabant. 3D printing has already been used to visualize bone fractures, but pioneering researchers believe it can also be used to help treat trauma patients.

Surgical Planning Using 3D Printed Bones

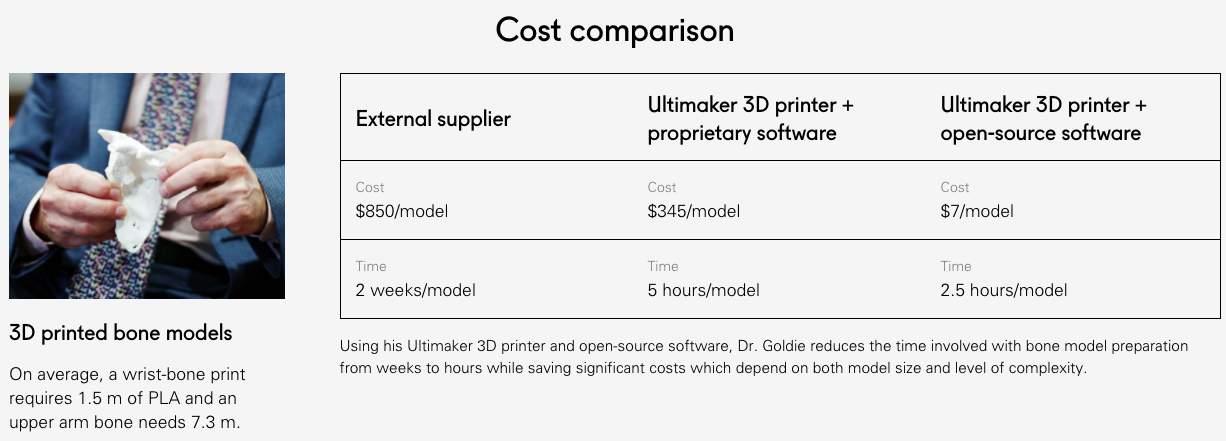

Boyd Goldie, an orthopaedic surgeon working in a private hospital in London, treats patients that range from emergencies to non-emergency elective problems covering a whole host of upper limb surgery.

"With modern radiology software you can get a virtual model on-screen, but there’s nothing like holding a model in your hands"

Ultimaker Gains Certification as Part of Materialise 510(K) Cleared Mimics Inprint Software

Furthering Ultimaker's dedication to reliability and accessibility, the Ultimaker S5 has been certified by Materialise as a 3D printing solution to create create orthopedic, maxillofacial, and cardiovascular models for clinical use when used in combination with Mimics inPrint software. The company partnered with Materialise to identify compatibility of the Ultimaker S5 with Materialise Mimics inPrint software to meet FDA regulatory guidelines for point-of-care 3D printing in hospitals.

Prosthetics / Orthodics

A 3D printed leg or arm prosthetic costs a hundred times less than a standard custom prosthetic, and can be created within hours. Utilizing a dozen Lulzbot machines, some of them modified to a 4 foot build height, and the strong and flexible Ninjaflex material, Protosthetics creates custom prosthetic attachments. Nia technologies even took their 3D printer and a 3D scanner to Uganda to create prosthetic sockets, fulfilling the country’s great need for these devices while cutting 80% in development time. The same thing happened in Haiti where 3D printed prosthetics created by researchers and local professionals to help disaster victims not only physically but also socially.

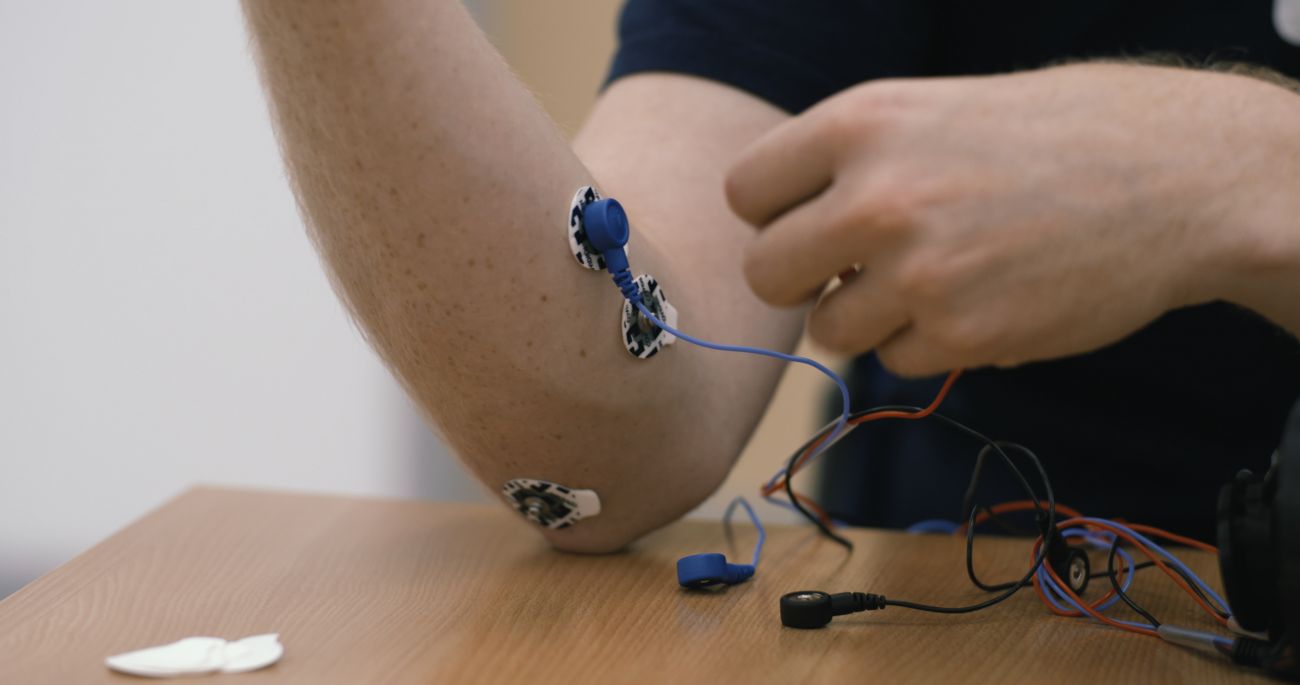

The company OpenBionics goes further and creates myoelectrically controlled artificial hands with integrated flexible joints re-empowering patients with the ability to perform subtle grips.

At FutureHear, ear prosthetics are created with help of photogrammetry to capture the shape of a patient’s ear, and 3D printing for creating a mold in which a silicone prosthetic ear is cast. Inner cartilage structures are directly printed in Ninjaflex. A digital workflow can enable remote care in developing countries, battlefields and hard to reach areas. There are ample applications showing the almost unlimited possibilities.

Do you want to recieve more helpful articles like this one sent right to your inbox? Sign up for our newsletter today!

Visualization Models

It is relatively simple making the step from a CT-scan to a 3D printed object, and that is the reason why several doctors and surgeons are starting to integrate 3D printers into their workflow. Dr. Boyd Goldie for example saves $800 per model and two weeks of lead time by printing bone models on his Ultimaker 2+. Also in London, dr. Andrew Phillips creates leg bone models out of nylon to evaluate the impact of blast injuries.

At Cranfield University, researchers are using Ultimaker printers to develop objects that help medical professionals study fluid paths, enabling better and haptic ways for experience-based training. Researchers at Jagiellonian University in Poland have combine 3D printed structures with transparent molded silicone to create detailed liver models with gains in time and budget. Also replicas of hearts, colons, unborn babies and cancerous structures are created on desktop printers to assist in complex surgeries.

Doctors agree that having a tangible model available greatly aids understanding and pre-surgery planning.

A physical model also comforts relatives of the patients with the knowledge that the professionals involved have already seen a tangible version of the patient’s organs or bones. It can even bring people a lot of joy for example where ultrasounds are converted into tangible models of the babies of visually impaired parents.

Clear communication with patients

Visual and tactile representations of the problem are helping doctors to explain difficult diagnosis in a clearer way to their patients.

Quickly validate designs

Medical products need to be up to the job. With 3D printing, iterative agile development helps you to hone it to perfection.

Pre-plan surgeries to improve outcomes

3D printed models help to improve accuracy, reduce operating times and give a better idea of structures in critical anatomical areas.

As we have shown, there are countless emerging opportunities to take advantage of the benefits around 3D printed healthcare solutions, with only a desktop 3D printer. The machines that we offer at Print Your Mind combine the versatility of handling many different types of materials while bringing you the greatest print quality, so you are ready to experiment and develop at your heart’s content.