Have Questions?

-

Only Top Quality Products

Only products from trusted brands

-

Personalized Services

We respond within 24 hours

-

Secure Payment

100% SSL Secure Payments

-

Canadawide Shipping

Free shipping on orders $99.99+

XSTRAND™ PA6 Glass Fiber Nylon is an engineering grade 3D printing filament is developed by Owens Corning, a world leader in glass fiber composites.

Key filament attributes:

- Reinforced PA6 nylon filament with 30% glass fiber

- Up to 250% stronger than ABS (Tensile Modulus (MPa) ISO 527)

- Designed for functional prototyping and industrial applications

- Excellent layer adhesion and reduced warping effect compare to neat materials

- Very stiff and strong materials

- Large operational temperature range -20°C to 120°C Good chemical and UV resistance

Spool dimensions:

Weight: 500g

Filament diameter: 2.85mm

About XSTRAND™

Up to 250% stronger than common filaments, XSTRAND™ GF30-PP AND GF30-PA6 ensure high performance and wear resistance in the most extreme conditions. Developed with superior durability, XSTRAND™ products give you the ability to design and print parts on site in a fraction of the time at a fraction of the cost. Advantages include chemical and UV resistance, thermal stability, superior durability, easy to use, high performance, design flexibility and the ability to test solutions in real world conditions.

Warning:

XSTRAND™ is an abrasive filament due to its glass reinforcement. For this reason we recommend using a steel hardened nozzle when printing with this material.

Reccomended upgrades for for Ultimaker:

Ultimaker Print Core CC Red - 0.6mm

Ultimaker Adhesion Sheets

Reccomended upgrades for Lulzbot:

HS Tool Head | Hardened Steel | 0.8 mm

HS+ Tool Head | Hardened Steel | 1.2 mm

Frequently Asked Questions (FAQ)

What is the optimal print temperature?

- PA - 240 - 260°C

- If using adhesive solution (packaging tape, HDPE bed, etc.), much lower in the range of 30-50°C

What are the applications for the material?

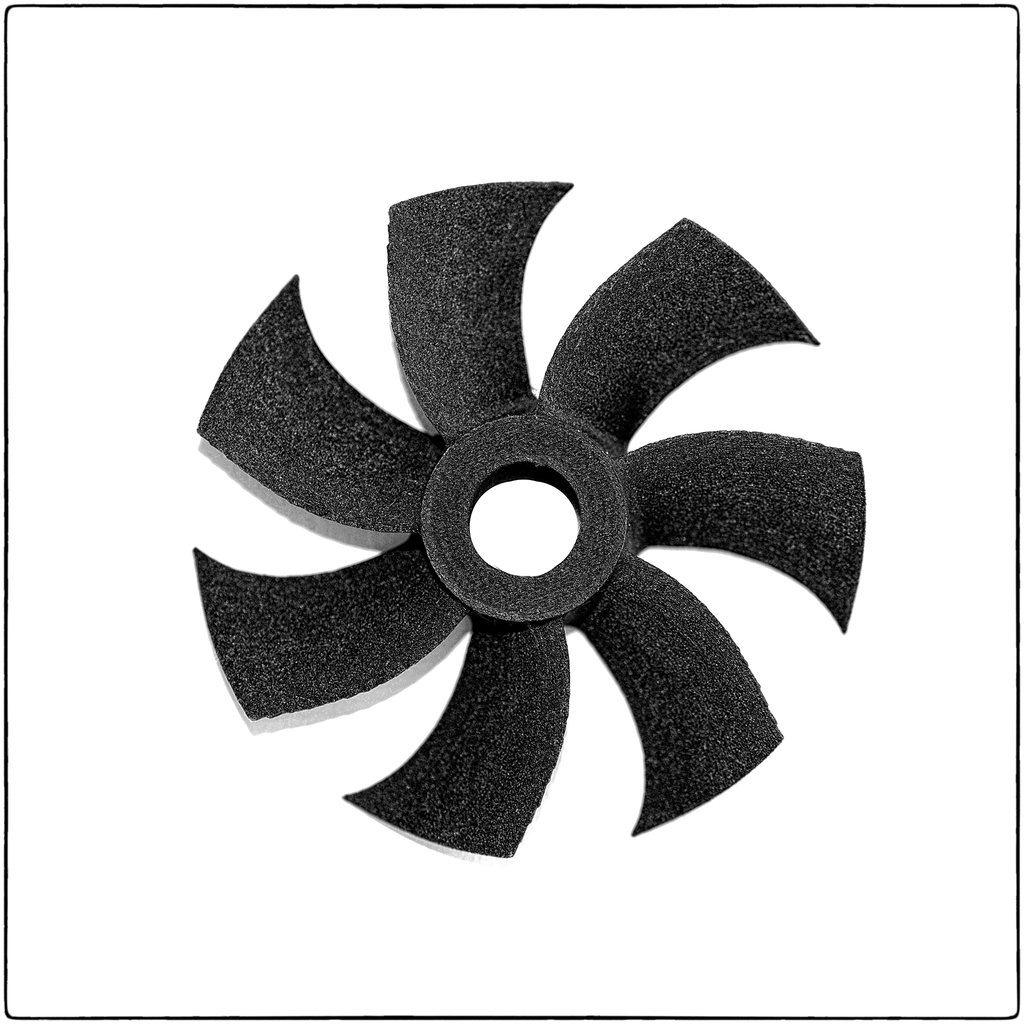

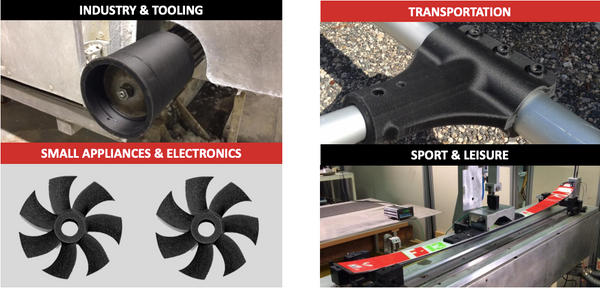

- Industrial usage including tools, fixtures, heavy duty replacement parts.

- Sport and leisure parts.

- Electronics and appliance parts, and many others.

How quickly does it degrade your hardened nozzle - e.g. how many grams printed before replacement?

- On the ulti-maker, we have 2,432 hours of successful prints with GF-30 PP and GF-30 PA6 using the same tool steel nozzle.

What is the difference in surface finish between the two XSTRAND™ GF-30 PP and GF-30 PA?

- The GF-30 PA6 feels a little rougher and the GF-30 PP is silkier.

How much temperature can the printed part handle? Wet or dry?

- This is linked to the Heat Temperature Deflection Test. We chose the highest ISO standard value at 1.8MPa and both materials standard specimen is handling 120°C in temperature. For this standard test, material are conditioned 48h at 23°C and 50% moisture air before the test. However, this is a general value that is totally dependent to the part geometry.

How is XSTRAND™ filaments different than carbon fiber filled PA or PP?

| Leading Brand of CF Reinforced PA6 | Owens Corning Glass Fiber Nylon | |

|---|---|---|

| Tensile Modulus | 4387 MPa | 7400 MPa |

| Tensile Strength | 64 MPa | 60 MPa |

| Heat Deflection Temperature | 102°C (at lowest pressure of 0.45 MPa) |

124°C (at lowest pressure of 1.8 MPa) |

| Flexural Modulus | 5650 MPa | 6100 MPa |

| Flexural Strength | 78 MPa | 170 MPa |